Industrial Components

Some of the metals like Mild Steel, galvanized steel, stainless steel, aluminium, copper, brass and engineering plastic are mainly used for making some of the tiny to important components that are used in machineries and mechanisms in many industries. We are one of the leading manufacturers of important industrial components and we supply these important components to many of the reputed industries.

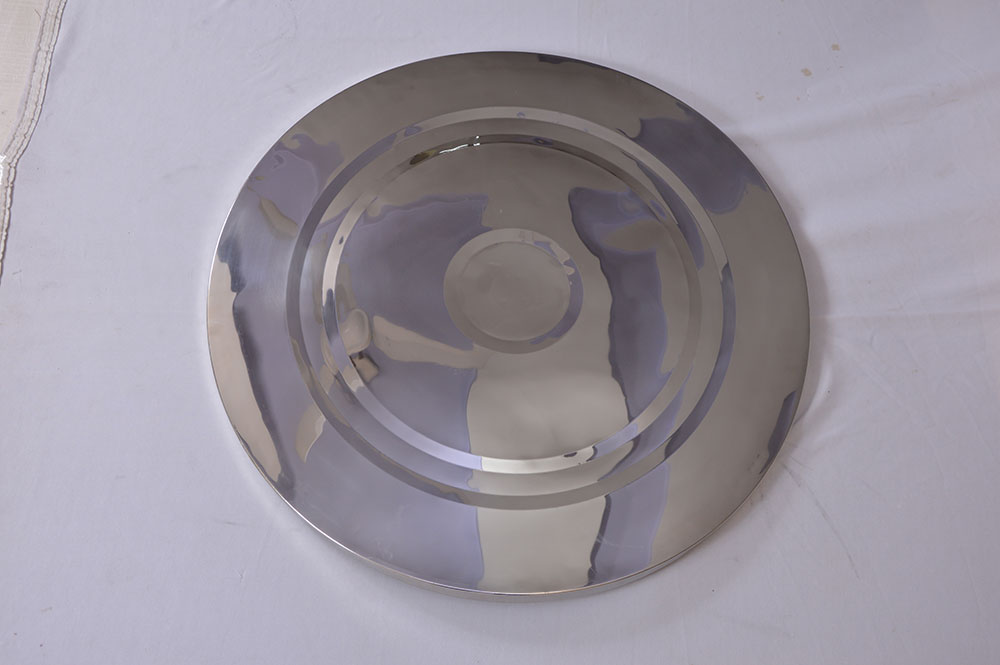

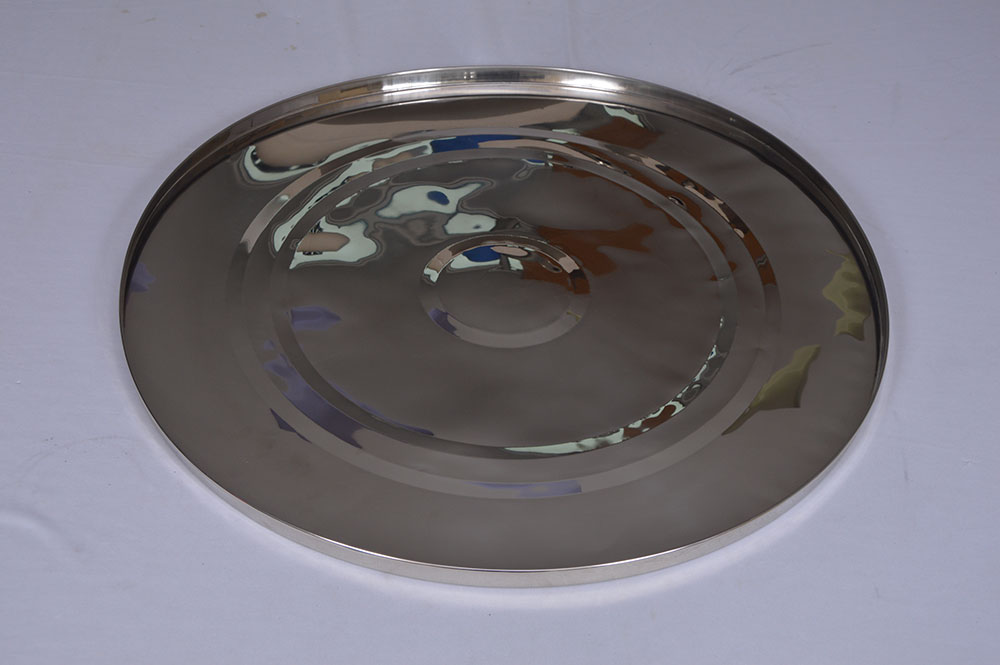

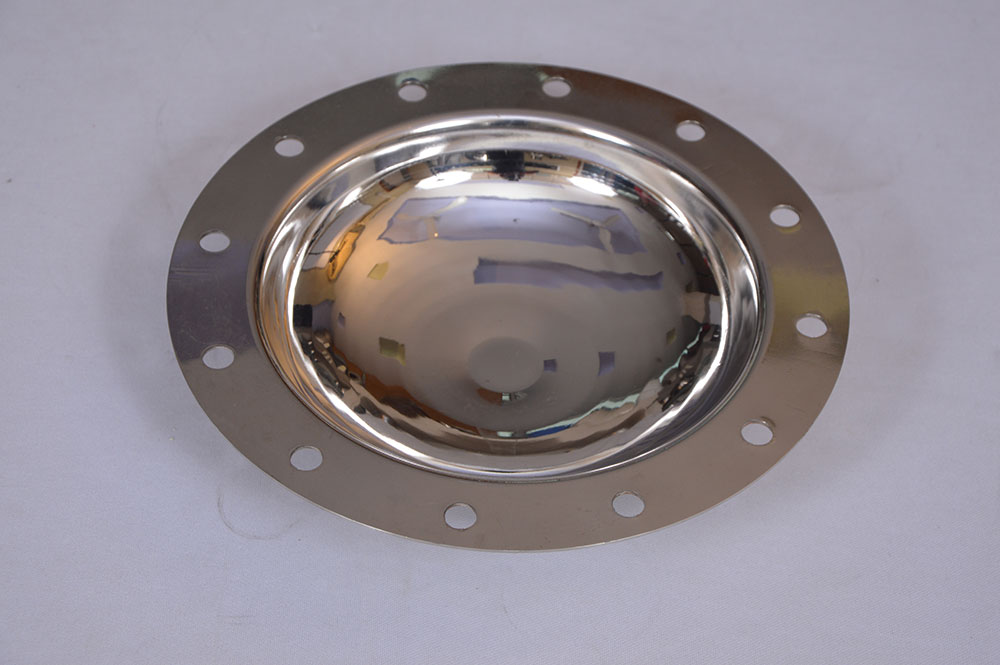

We are into drawing to sheet metals to components, to reduce the cost and provide customers with the tailor made industrial component. We take pride in doing so because this is one of the remarkable features where we convert the metal sheet into components of a particular type and design. It depends completely upon the customer's choice.

Well, only the process of manufacturing is not enough because it has to reach the customers in its best form. Therefore it is important that testing and quality check is carried out at each step. Therefore all these components , raw materials and processes are physically monitored, mechanically checked and chemically tested to ensure that they are made of the best quality.

Processes for components like Tooling, Punches, Dies (Progressive, Compound, Transfer & others). Input Raw Material Forms (Rolled Sheet / Coils / Blanks / Circle), Shearing / Slitting / Cutting, Punching / Blanking / Stamping / Embossing, Bending / Deep Drawing / Extra Deep Drawing / Stamping / Roll Forming / Slide Forming, Metal Welding, Secondary Processes (Coating / Heat Treatment / Joining / Welding / Plating / Anodizing / Etc.

Industry we served are Electricals & Energy, Hydraulics / Pumps / Motor, Referigerations, Water Heater, Electric & Solar, Water Purifier, Agriculture, Textile & Plastic Machinery Industry, General Industry.

Shri Navkar Metals Ltd has always tried to perform above the customers expectation, the same is been witnessed by one of our Buyer. We successfully replaced Casting Heavy Component to Sheet Metal Component, this couldn’t have been successful if there would not have been any confidence from our Management team to Technical Team and Work Force. With each other support we could develop this component, we not only solved the problem of our customer by reducing waste of raw material, rejection but it gave them elegant design, less then 30% use of raw material, reduction in cost by more then 80% and durability too.

We have successfully holding LIMCA Book of Records for the Largest Deep Drawn Component (Non Welded / Joint Less Category).

Product Gallery

Request a call back

Would you like to speak to one of our Sales Executive over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.